Foundry and forging production

Main types of activity: production of cast sections and stamped blanks. Productivity of the forging shop of the plant: 1,800 tons per annum. The plant is capable to manufacture stamped blanks made of the structural-grade steel and stainless steel, as well as of aluminum, copper, and titanium alloys.

PRODUCTS

Cast sections and stamped blanks for aviation industry and other branches of national economy.

FOUNDRY PRODUCTION

1. Specialization of the foundry production of the Plant: manufacture of cast products made of the structural-grade steel and stainless steel, as well as of aluminum, copper, and titanium alloys for aviation industry.

2. Organizational structure of the foundry production of the enterprise:

– modeling shop;

– lost-wax casting shop; productivity – 100 tons per annum;

– Iron castings shop; productivity – 120 tons per annum;

– pressure-die casting and permanent-mold casting shop; productivity – 100 tons per annum;

– aluminum foundry shop; productivity – 100 tons per annum;

– lost foam casting shop; productivity – 50 tons per annum.

3. Main process equipment:

3.1 Foundry equipment: induction-arc furnaces IST-0,16; gas-fired double-crucible furnaces, electric crucible furnaces for aluminum melting.

3.2 Sand cutting-and-screening machinery and core assembly equipment: pan mill-processing machines 1A11.

3.3 Equipment for special casting methods: die-casting machines 711A06; 711A07; 711A09 H-600D; H-400D; H-250D; as well as gravity die casting machines 5922; 5924.

3.4 Cleaning equipment: sand-blasting apparatus A-25.00.00.0; sand-blasting chamber НО260

3.5 Heat-treatment machinery: PAPZM; PAP4M; TS105 (Ц105); PN34.

4. Standard cast products: enclosure, levers, mounting brackets, flanges.

5. Manufacture of foundry technological equipment: cast iron molding frames, all-welded molding frames, casting molds, combination die equipment for lost-wax casting, steel injection molds for pressure-die casting.

6. Pattern-making: gated patterns made of wood, aluminum alloys.

7. Quality control techniques: rapid analysis of chemical composition, chemical analysis, testing of mechanical properties, microstructure determination, photocolorimetry, X-ray diffraction analysis, electroscopy, air tightness check, dimensional accuracy control, pouring temperature control, control of properties of molding materials and core assembly materials.

8. Additional possibilities: application of primer coat, heat treatment, machining treatment.

FORGING PRODUCTION

1. Specialization of the forging production of the enterprise: manufacture of stamped blanks and forging blanks made of aluminum, copper-bearing, titanium, and steel alloys.

2. Productivity of the forging shop – 1800 tons per annum.

3. The Plant has possibilities for production of fences, railings, and fireplaces in accordance with the rough drawings submitted by customers and the enterprise’s samples.

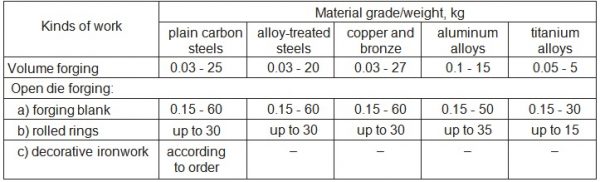

4. Specialization of the forging production in respect of grades and weights of various materials.

5. Main process equipment:

– presses with powers as follows: 630 t, 800 t, 1,000 t, 1,600 t, 4,000 t

– forging hammers with the following masses of driver assemblies: 196 kg, 400 kg, 1 t.